Moving Mountains

CU Boulder’s College of Engineering and Applied Science uses VERICUT to improve student outcome.

The tail end of the 2019/2020 school year has been challenging for students and teachers alike, but with a little luck and continued social distancing, the bad times will be gone for all of us by the fall semester. If so, Cameron Micksch and the rest of the faculty at the University of Colorado Boulder will be ready to pick up the academic pieces and get back to work.

Meet the ITLP

A manufacturing specialist for the College of Engineering and Applied Science’s Integrated Teaching and Learning Program (ITLP), Micksch and machine shop manager Mark Eaton are responsible for teaching engineering students the inner workings of manufacturing. This includes CAD/CAM, 3D printing, materials science and product design principles, and CNC machine tool operation. Especially the latter.

One of the tools the ITLP uses to accomplish this? VERICUT toolpath simulation and optimization software from California-based CGTech Inc.

“Our program supports students enrolled in four-year engineering degree programs,” he said. “These could be freshman-level projects where they’re tasked with designing and then manufacturing a product, all the way up through post-graduate research and development activities. We also work with the school’s instructors and professors on various manufacturing-related activities, some of which are driven by corporate sponsors.”

Bridging the skills gap

The skills learned in the ITLP go far beyond learning how to operate manual milling machines and engine lathes. Yes, the wood and metal sides of the shop have the usual complement of drill presses, bandsaws, and the like, but there are also CNC routers, CNC knee mills and lathes, and the two stars of the show, VM10i 3-axis and VM10Ui 5-axis vertical machining centers from Hurco. It was this second machine that led Micksch to VERICUT.

“We acquired the Hurcos in 2017, and it quickly became clear that our CAM software was fine for basic 3+2 positioning work, but didn't really cut the mustard when it came to five-axis simultaneous programming," he said. "That, and since there was no way to verify the actual G-code, we felt we needed a better tool to visualize the machining process, and simulate what would happen before pushing cycle start.”

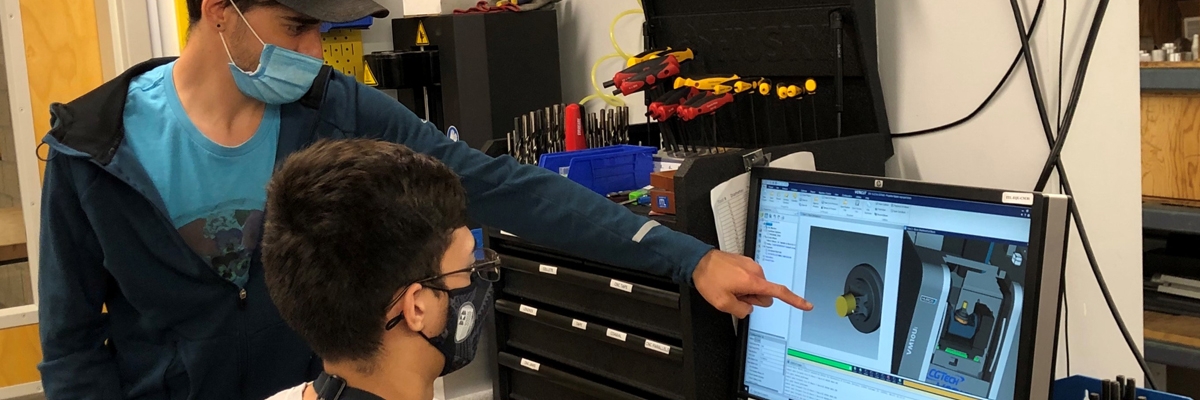

Because most of the people coming through the ITLP have little to no experience in machine operation, let alone CAD/CAM or toolpath simulation and optimization software, VERICUT is more for Micksch’s use than that of the students. Still, he works one-on-one with them to generate the CNC programs, then runs the resulting toolpaths through VERICUT to check their work.

“A fair share of the students entering this program have the impression that CNC machining is like an Easy-Bake oven, and all they have to do is write a program and let the machine tool do the rest,” he said. “VERICUT gives them a chance to see the entire process and learn how machining works. They can learn what went wrong and how to change it, and identify any opportunities for improvement. And from my side, VERICUT eliminates any concerns that they'll inadvertently damage one of our Hurcos.”

Counting the successes

To date, roughly 300 students have graduated from the ITLP’s CNC courses, but Micksch is quick to point out that 700 or more use the shop each academic year for other reasons. There are numerous student-run engineering groups, such as the school's rocketry club (CUSRL) and Formula SAE, an international competition where students have the opportunity to design, build, and drive Formula-style race cars. "We helped make some crazy steering knuckles for them on the five-axis last summer, which was pretty cool,” he said.

The school also does research work with grant money from local and national businesses. These might be specialized medical devices for one of the area's hospitals, enclosures for reading radioactivity, or components produced for leading aerospace companies. "One of our clubs is called Space Grant, which is funded in part by NASA, and one of my students went on to work with one of their subcontractors," said Micksch. "Granted, our use of VERICUT had very little to do with that success story, but a large portion of our students get hands-on experience on the Hurcos, and my job would be much more difficult without VERICUT. That, and it’s a great teaching tool.”

Article published in CNC West magazine, October 2020

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan