Drilling & Fastening

When working with expensive airframe assemblies, the cost of drilling or fastening mistakes is high! How much time do you spend avoiding them?

VERICUT Drilling & Fastening (VDAF) can help you avoid problems such as:

VERICUT Drilling & Fastening (VDAF) can help you avoid problems such as:

- Drilled hole or fastener in wrong position

- Missed hole or fastener

- Wrong hole size or fastener in right position

- Hole not drilled through the stack

- Hole double-drilled or double-filled

- Wrong fastener for material stack

- Collision with structure

- Collision with tooling

- Collision with added fasteners

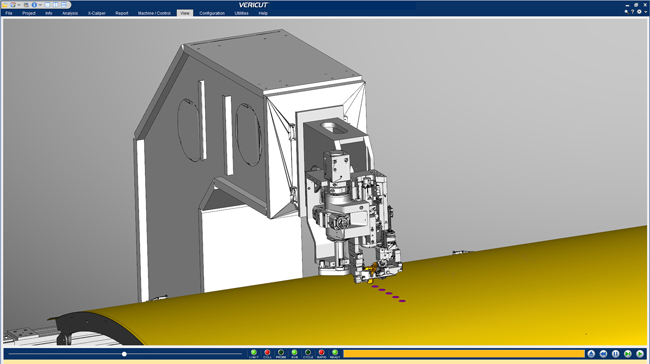

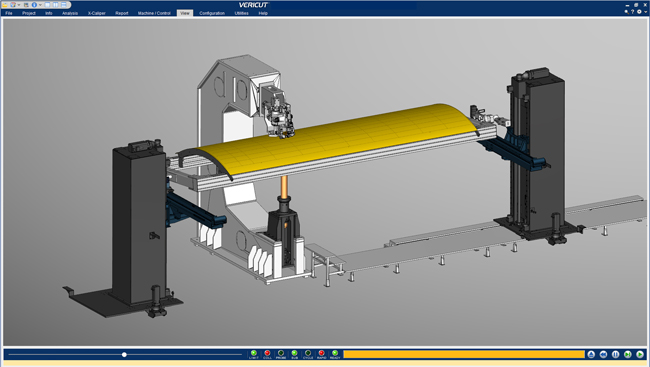

VDAF Simulation

Visualize and simulate CNC drilling and fastening machines using the same NC program code that will be run on the machine. Simulation is independent from programming, and VDAF can simulate NC programs from any programming system for any CNC-automated drilling and fastening machine.

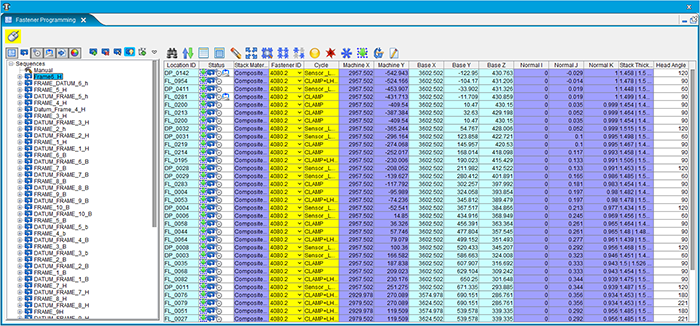

VDAF Programming Add-on Option

This add-on module to VDAF gives you the ability to create NC programs for CNC auto-drilling and fastening machines. Fasteners are displayed in a tree dialog that allows you to group fastener types under tree branches and order them as needed.

VERICUT Drilling & Fastening is based on industry leading VERICUT Software. VDAF is designed to create and simulate NC programs for automatic drilling and fastening machines, also called “layer drilling” or “riveting” machines.

Product Descriptions - VDAF Simulation

The base simulation software is used to visualize and simulate drilling and fastening from NC program code. VDAF simulation is a universal software application capable of simulating multiple CNC auto-drilling or auto-fastening machines. A single license can simulate multiple different machines using a VERICUT Machine Configuration (VMC) configured for each machine. Every VDAF implementation requires at least one VMC.

VDAF simulates machine motion directly from NC program files to check for collisions and other potential process problems. VDAF simulation also checks specific auto-driller/fastener actions, such as: proper drilling and fastening through the stack, appropriate tool selection for specified hole or fastener parameters, properly inserted fastener for given hole and stack call-out, collisions with inserted fasteners.

A Tool Library organizes the drills and countersinks to be used in a simulation session. A Fastener Library contains models of specific fasteners that can be inserted by NC program commands.

VDAF Programming Add-on Option

This add-on module to VDAF Simulation creates NC programs for automatic drilling and fastening. This is a universal software application capable of programming many CNC auto-driller/fastener machines. A single license can program multiple different machines using a post-processor configured for each machine.

The assembly to be programmed within VDAF contains an individual part model for each member of the CAD assembly, located in its proper assembled position. Each part’s material is identified, as well as the clamp surface and any fixturing. VDAF’s fastener locations are created from the CAD model’s fastener locations and attributes, as read by the custom-tailored fastener reader utility. Fastener locations contain the attributes of a fastener and its location in the assembly. The set of fasteners and their attributes define the drill and fastener cycles to be used.

One or more reference locations may be selected, typically at Drilled at Assembly (DA) holes or temporary fastener locations. These selections invoke machine reference operations, but typically do not affect nominal locations in the NC program. Hole or fastener locations are grouped by local and global reference locations. Designating and activating reference holes create commands in the NC program to align the operation to the physical part.

Fasteners and operations are displayed in a tree dialog. The tree layout allows the user to group fasteners under tree branches and order and re-order them as needed. The user interface clearly identifies the fasteners that have been processed and those that have not. Fastener information can also be displayed in different ways to meet other user requirements. For example, fasteners may be displayed by type, diameter, length, etc. The VDAF Programming Add-on Option requires a VDAF Simulation base license.

VERICUT Machine Configuration (VMC)

A VMC reads the auto-drilling/fastening NC program for a specific machine. It contains the definition of all drilling, fastening, utility cycles, and functions used in the NC program. It then emulates the CNC control logic necessary to accomplish a simulation of the NC program on the specific machine, including simulated fastener insertion. Simulated fastener insertion requires CAD models of the various fasteners that will be used in the assembly process (stored and organized in the Fastener Library).

Post-Processor

The post-processor formats the auto-drilling /fastening paths created in VERICUT for a specific machine. The post-processor contains the definition of all drilling, fastening, utility cycles, and functions used in the NC program.

Other Possible Requirements

CATIA & NX Interfaces

You can verify individual operations, a series of operations, or a set of complete NC programs. All Skins, Fixtures, Structures and Fastener locations are automatically transferred to VDAF in the correct orientation, along with your NC program, machine and control data, and other simulation parameters. Also, the optional 3D model interface modules allow VDAF to directly open native CATIA and NX part files.

Custom Fastener Object Reader

A custom script running inside the CAD system that reads user-defined fastener information and converts it into a VERICUT fastener file, in preparation for programming and simulation. This script is custom-written for each end-user implementation.

Vistagy SyncroFIT Interface

A standard interface for reading the assembly, fastener definition, and process information from SyncroFIT’s Airframe Design Environment, and prepares files for programming and simulation in VDAF.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan