VERICUT proves to be the winning formula for the motorsport industry

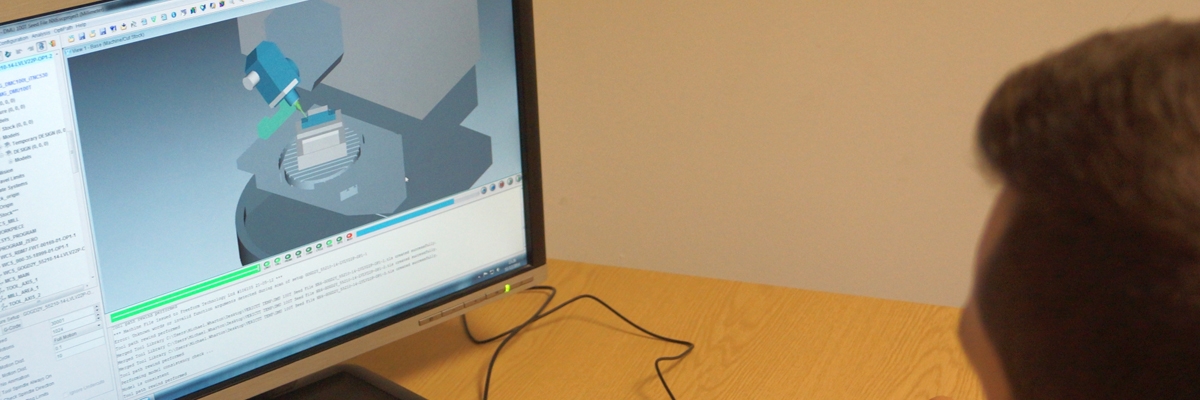

Supplying the Formula One and motorsport sector, Freeform Technology has quickly established its enviable business reputation on the fundamental elements of any race team – precision and passion, as well as the commitment to go the extra mile to ensure its promise to any customer is fulfilled. The company uses CGTech’s VERICUT, the world’s most advanced independent CNC machine tool simulation and optimisation software, to achieve these goals.

Established in 2008, the majority of Buckingham-based Freeform Technology’s work is connected to the motorsport industry. This might be expected as co-directors knew each other when they both worked at Red Bull Racing. Company Director, Simon Burchett, explains: “At least 80 per cent of our work is F1, and then there’s the non-F1 side of it that’s still motorsport. The balance is made up of subcontracts and composite companies that need additional capacity or pattern machining, many have their own pattern shops so we act as an overflow capacity for them.”

Having decided to form a subcontract engineering company they were well aware that while the metalworking side offer huge opportunities, there were also many companies who wanted to do it, making it a ruthless industry sector with high start-up costs. Subsequently the decision was made to focus on producing patterns and moulds for the ever increasing composite components.

The Red Bull pattern shop had three Breton machining centres, “so the first thing we did was go to the company that supplies them to work something out,” recalls Simon Burchett. “However, the finance package was beyond us at the time so that was a non-starter. We looked at second-hand machines, but nothing suitable was available so we approached CMS Industries. The price seemed more reasonable and we flew out to the factory in Milan, Italy. We were both very impressed with the company so we came back to get the finance in place, bit the bullet and re-mortgaged the house just at the start of the global recession.”

He continues: “Fortunately for us Red Bull did help us out with work and free-issued material. We have found that like Red Bull, many of the F1 teams we have worked for are very mature and supportive, they really appreciate a supplier that does good work and they don’t want to lose them so they’ll do what they need to do to make sure you keep going.”

The new CMS machine came with a warranty of 3,000 hours or 12 months, whichever came first and not many businesses hit that in the first year, Freeform clocked it up within nine months because it had to keep it running all the time. “It was our only machine, our only source of income, we were working from 6 am until midnight and if at any point in the first year that machine went down we would have gone bust,” Simon Burchett states.

Having used VERICUT at Red Bull both partners were keen to invest in the simulation and optimisation software. Simon Burchett says: “We could not afford it until the second year, and going home at night leaving the machine running wondering what you would return to in the morning was quite worrying.

“We always had VERICUT at Red Bull as it was part of the process, so not to have it was stressful to say the least. As soon as we could afford it, we invested in the software because it is not just for big businesses. With only one machine you have to protect it, if it goes down then you are effectively unable to work, and when the machine breaks it cost so much to fix. After a major break-down you think ‘with that money I could have had VERICUT’. We felt it was a false economy not to have the level of protection offered by the software. Other small companies see it as a massive overhead; we see it as an essential tool of cost cutting and survival in the long run.”

Every one of the 13 staff at Freeform will push the start button, go home and be confident to let the NC program run until the end of the machining cycle. “And,” Simon Burchett adds, “the quality of work we provide would be affected by a machine tool that had suffered a crash because the accuracy of the machine will be affected. So as soon as we could get VERICUT there really was no hesitation.”

After turning over a modest profit in the first year the company purchased another machine tool and started to employ highly skilled staff. Although the company was tight on floorspace a project for Renault F1 (Lotus F1) for brake ducting components required around 18 patterns. This made the investment crucial. The tolerances were very tight because any air leak would reduce efficiency, and a new DMG machining centre was purchased to meet the project demands, and to also provide the ability to machine metallic components. Today the company operates three CMS machines as well as two DMG machining centres.

Native Siemens NX 3D CAD models are supplied by most customers. Simon Burchett says: “We’ve had VERICUT for just over three years and its performance is always robust, it’s always been what you think it’s going to be, very accurate, it’s not going to throw up any sort of spurious mistakes. Using the latest version of VERICUT we’ve noticed the difference in verification speed, it has been reduced considerably and we can leave it run over night.”

Four staff at Freeform carryout programming and verifying tasks, but the company is looking to train more people because at busy times it can become a bottleneck. “Having four people programming with two VERICUT licences is never going to be that easy,” Simon Burchett says. “We will need another licence but I don’t have a problem paying for it. We see it as a working overhead, it is a key investment as far as we’re concerned, having a machine that is smashed up and unable to make the parts accurately is a liability,

“There is no point cutting a piece of material for three or four hours for it to be wrong because the cost to do that is considerable. It’s not just the cost of remaking the part, it is the cost of not being able to do another job while you are waiting for that one to be finished – again. Our objective is to make sure what goes on the machine comes off right the first time. Mistakes upset the customer, ruin your machine and business, and a five minute lapse of concentration that leads to a mistake can effect a week of work, it becomes counter-productive. Staff then have to work longer hours and get tired, the morale drops and the standard of work declines.”

For Freeform VERICUT simulation and optimisation software is as important as its CAM package. “We’ve got to have faith in our CAMpackage, when we do a tool path it’s not going to gouge the part for some random reason as we apply complex tool paths. We have 100 per cent confidence in NX and 100 per cent confidence in VERICUT, so it’s almost like an additional safety net for us. Our staff are also confident, which allows them to do one job, leave it and then set up there next job,” Simon Burchett explains.

Freeform prides itself on the fact that it has earned a good reputation for delivering quality, and has never delivered anything late. “Even though we have stretched the day,” Simon Burchett explains. “Most people would say the working day ends at five, we’d say midnight.”

Today, even if there’s just a slight change to the tool path nothing goes on the machine tools unless it has been run through VERICUT first; purely and simply because it’s safe.

Simon Burchett concludes: “As soon as we got VERICUT we could programme to run through the night, knowing we could leave the machine running for the extra hours and it would be safe. Sometimes we come in the morning and the machine is still running. If you think that if we didn’t have VERICUT then there is the chance you are going to come in, the machine has mangled the part which cost thousands and the jobs not done, your customer is not happy, you are not getting paid, the machine is broken and going to cost to repair. So for us not having VERICUT was not an option and also we can sleep at night.”

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan