Engineering service provider Noble Technologies Corp (NobleTek) says VERICUT plays a big role in keeping customers happy

Every CNC machine shop everywhere has faced the same problem at one point or another: the programming office is backed up, and how are we going to keep the machine tools running? For some, the cyclical nature of the machining industry can be a nearly insurmountable challenge, leading to late deliveries, lost productivity, and unhappy customers.

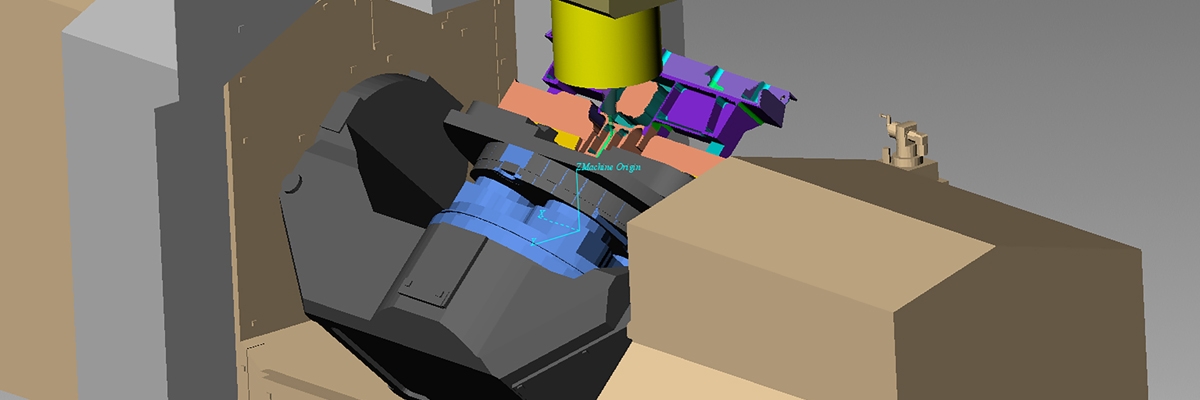

For the customers of Wooster, OH.-based NobleTek, one of the tools that Casey Carson and his fellow CNC programmers use to assure high-quality deliverable for their customers’ is the toolpath simulation and optimization software VERICUT from CGTech Inc. in Irvine, California.

Early discoveries

Carson has only been with the company a little over one year, but he’s been using VERICUT at various programming and engineering jobs for more than a decade. It wasn’t until he was several years into it, though, that a friend of his introduced him to some of the software’s more advanced features. Carson was hooked.

“He’s the one that taught me the true value of VERICUT,” Carson says. “Before that, I’d been using VERICUT in the same way that many of our customers do—as a means to avoid crashes. But there are lots of little things like advanced reporting, automation, graphing of the cutting forces and so on that many people don't realize are available in the base software. These are tools that any shop can use to make their programs run better and improve overall shop efficiency.”

Lending a helping hand

NobleTek’s mode of operation is a team approach blended from both on-site and off-site professionals to meet their customers’ project demand. NobleTek provides a variety of value-add services that go well beyond CNC programming, including robotic programming, composite manufacturing, 3D Design, data conversion and more. For Carson and his fellow programmers, though, a typical day involves taking the customers CAD models and providing them with a proven, efficient, and above all crash-free set of NC toolpaths.

Carson focuses most of his efforts on CATIA programming, while others in the department might use NX, Mastercam, GibbsCAM, or any of several other leading CAM packages—as a rule, they use whatever software their customer is using, so as to maintain as seamless a handoff as possible. This includes VERICUT.

“I guess we have a leg up in that respect, because most of our customers—the ones I work with anyway—are in the aerospace industry, and I’ve yet to see one that wasn’t using VERICUT,” he says. “That’s a good thing, because accurate toolpath simulation is so essential to achieving what was intended when you’re programming the job.”

Cost-avoidance AND crash-avoidance

Before working at NobleTek, he had many discussions with former employers about the seemingly high cost of VERICUT. His response was straightforward, and should be obvious to anyone who’s worked in a machine shop as long as he has. “It’s a lot cheaper than a new spindle.”

Carson explains that it costs a lot of money to prove out a part the old-fashioned way—by putting it on the machine and stepping through each line of code—but if you're running VERICUT, all of that hassle and expense is eliminated, never mind the fact that you’re not going to crash.

But let’s assume for a minute that the CAM system simulation many shops rely on really is “good enough,” and there’s nothing wrong with the argument, “We have great programmers, and machinists who are very careful.” What then? According to Carson, there’s much more to the justification equation than the off chance of a broken spindle.

“How many cutters do people break, how many parts are scrapped, how many minutes or hours are lost proving out programs because they didn't have VERICUT?” he says. “Then there are the things like automatic tool lists and setup sheets and all the different reporting capabilities—everything that you need to know about the job is in there, and all of these functions serve to make shops more efficient.”

Digging simulation

It’s clear that Carson is a big fan of toolpath simulation software. He’s in the not always enviable position of working with a variety of customers, each with its own unique blend of requirements, capabilities, and varying levels of VERICUT use. When asked how often the software has “saved his bacon” or that of his customer, he didn’t have to stop and think about it. “Every day,” he says.

The ability to bulletproof programs for others is especially important in today’s manufacturing environment, where much of the industry’s tribal knowledge is retiring, and those few coming into the trades are often less skilled. At the same time, parts are becoming more complex, materials more difficult, machine tools faster and more expensive, and production quantities are generally falling.

Throw the increase in robotics and unattended machining into the mix and it’s imperative that shops find the tools necessary to verify and optimize part programs long before the cutting tool first touches the metal. According to Carson, that tool is VERICUT.

“It’s such a small price to pay to find out if something works or doesn't work,” he says. “Simulation lets me know if I'm tearing my machine up, and VERICUT’s AUTO-DIFF function lets me know if my part's good. And when I send the program to the customer, they’ll use VERICUT to review how I ran the program and ensure that I’m cutting the part the way they wanted. It saves so much time, and so much money for everyone involved.” He laughs. “It’s a little crazy when you stop to think of all of the things that VERICUT can help you with. To me, it’s probably the most valuable tool a programmer can have.”

Article published in Aerospace Manufacturing and Design, June 2019 Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan