Create Better Parts in Less Time with Advanced NC Simulation & Optimization

Watch VERICUT Product Manager, Gene Granata, as he discusses Advanced NC simulation and optimization capabilities with VERICUT 9.0, and hear from guest speaker Brandon Eaton from Steelville Manufacturing Co. as he presents his experience as a VERICUT and Force Optimization customer.

Manufacturing technology is expanding at a frightening rate, making the case for simulation more critical than ever for machine tool users. VERICUT software allows users to build digital twin virtual machines, enabling manufacturers to create and “test drive” machines they do not own, modify existing machines (such as add auxiliary rotary tables or angled head attachments), or even design new machines that may better handle the task of making their parts. In addition, companies have learned they can share a wealth of information generated from simulation that benefits other departments and helps to create a seamless manufacturing process.

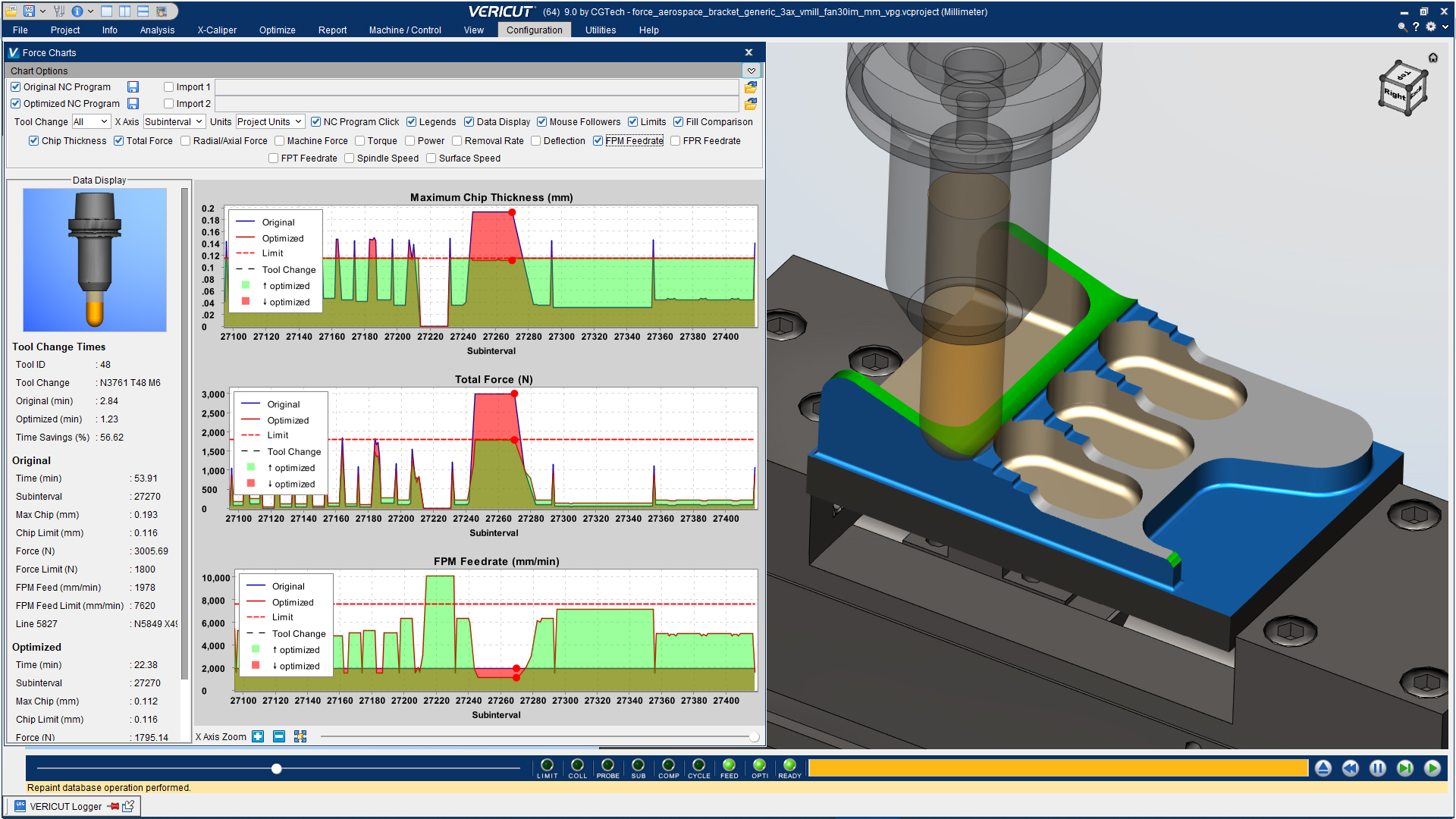

VERICUT’s latest version (9.0) offers major advancements in graphics technology, optimization, and AM. Enhanced graphics, more realistic appearances, a more flexible view environment and faster graphic rendering offer a unique win-win situation for users, and a best in class simulation solution for new users. VERICUT’s Force optimization enhances any new or existing NC program to remove material based on optimal chip thickness calculations, while also maintaining safe cutting forces and spindle loads. VERICUT’s advanced AM/hybrid manufacturing support allows AM parameters to be plugged into VERICUT’s Additive simulation, ensuring AM parts are built correctly and within proper limits to create a quality part.

Topics covered:

- How VERICUT software can protect your investment, increase shop floor productivity, and streamline data flow throughout multiple machining operations

- Why seamless connectivity between CAM, tooling and simulation software is crucial in today’s manufacturing environment

- How Force optimization decreases machining times by 25% or more, extends tool life up to 2X longer, and enables manufacturers to make better machined parts

- How VERICUT’s Additive capabilities provide the ability to add, cut- or cut, add… in any order, to verify hybrid methods will work, and are as efficient as possible

About the Speakers

Gene Granata

VERICUT Product Manager, CGTech

Mr. Granata, VERICUT Product Manager, has been with CGTech since 1992. With more than 30 years of CNC manufacturing experience, Mr. Granata is responsible for planning development of CGTech’s flagship software product VERICUT, and associated CAD/CAM and Tooling interfaces. After receiving his Bachelor of Science degree with an emphasis in NC Manufacturing Technology from Northern Illinois University in 1983, his professional career began at Bendix Aerospace (now known as Honeywell Federal Manufacturing & Technologies) as an NC Programmer for a variety of CNC lathes, mills, and multi-tasking machines. He then went to work for aerospace companies such as Northrop Aircraft and McDonnell Douglas, working on T45, F20 and F18 fighter projects, as well as B2 Stealth Bomber and C17 military transport aircraft. Prior to Mr. Granata’s role as VERICUT Product Manager, he was the Technical Support Manager, and has written technical documentation, designed many general-purpose and customized training courses, and provided manufacturing consulting services to hundreds of companies in virtually every industry.

Michael Fry

Practice Director for Manufacturing Systems Engineering, CIMdata

Mr. Fry has Over 40 years of PLM and manufacturing industry experience focused on product development, manufacturing automation, and systems engineering. Michael has extensive experience in client management, solution design, consulting, and business analysis. While at at IBM and later Dassault Systèmes, Michael worked with global manufacturing companies in the automotive, aerospace & defense, building products, fabrication, industrial equipment, and marine industries. Most recently, he worked at IBM in the predictive analytics discipline working on projects implementing the Internet of Things (IoT) and Industry 4.0 practices to provide data collection for cognitive computing and decision-making. This work was applied to machine tool operations, drone imaging and video capture, as well as jet engine failure prediction.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan