VERICUT 9.1 – Raising the Bar for Simulation

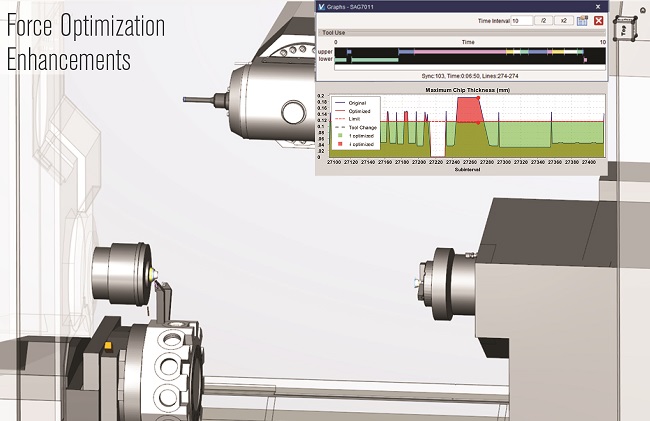

Force Optimization Enhancements

Faster, easier analysis and optimization setup with new Force “Learn” Mode and Force Charts enhancements. Learn mode introduces Artificial Intelligence (A.I.) for optimization; VERICUT learns from cutting while you simulate, automatically sets up tools for optimizing, and can auto-optimize the NC programs after learning. Using Learn mode, almost anyone can create highly optimized NC programs from existing programs that already run in the shop! Optimization for multi-channel machines allows you to optimize NC code that runs on all channels at once, or selected channels.

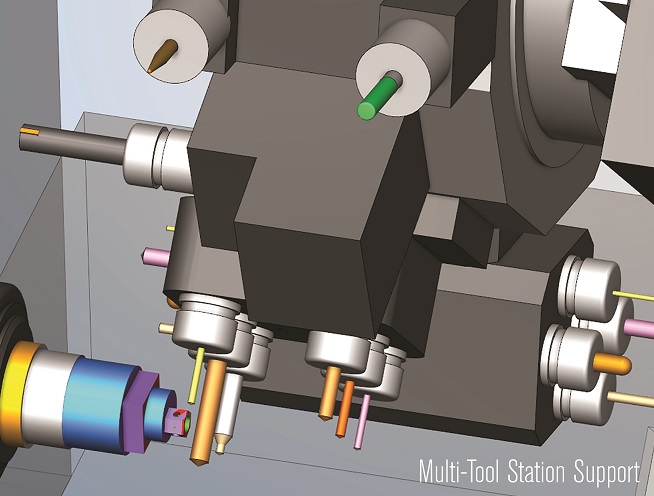

Multi-Tool Station Support

More robust support for tools arranged on Multi-tool Stations, including support for tap tools and “dead” (non-spinning) drills. VERICUT provides error notifications for motions that are not along the tool’s axis such as lateral tool motions, and when tap feed rates and spindle RPM will not produce the desired threads.

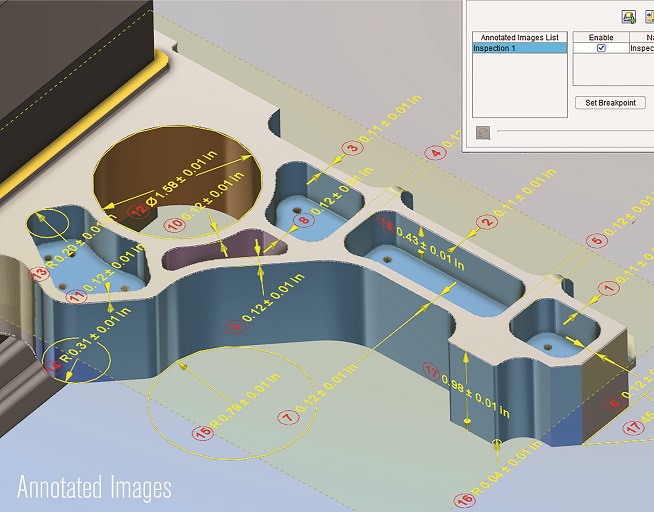

Annotated Images

Capture informative images with clear instructions that describe the Setup Plan for the machine. Create Inspection Plans with dimensions, notes and tolerances for checking parts at various stages of machining. Annotated images clarify what the machine setup should be and what to expect when running the part program to ensure the finished part matches the intended design.

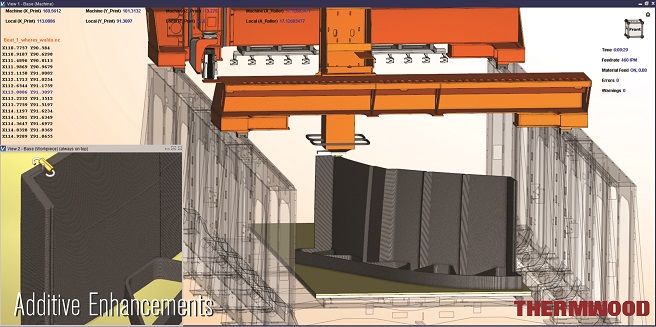

Additive Enhancements

Simulate Additive Manufacturing processes without the need for a starting stock model. Build nested additive parts and assemble them into “bonded” parts, or move them independently into subsequent setups for machining. A new “Additive” Default Machining Type enables VERICUT to make the best use of system resources to improve additive simulation performance, which is especially helpful for Big Area Additive Manufacturing (BAAM) and Large Scale Additive Manufacturing (LSAM) parts.

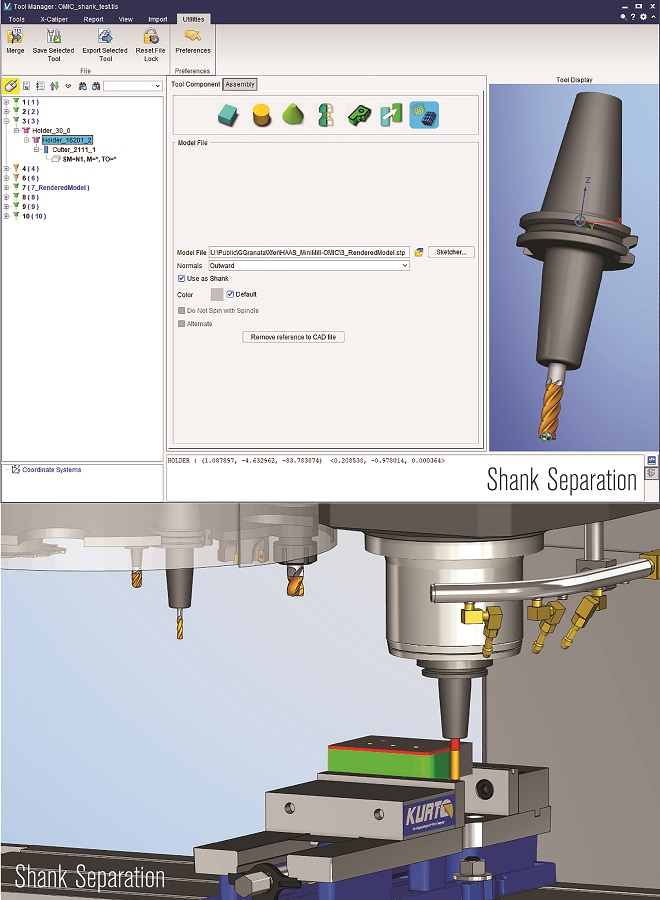

Shank Separation

Mill and hole making tools in VERICUT have greater control over describing the non-cutting “shank” portion of a tool assembly. Defining shanks as separate objects from the holder and the cutter enables programmers to see where the non-cutting portions of the tool are relative to the stock workpiece, and allows more discrete control over near miss and collision detection properties and tolerances.

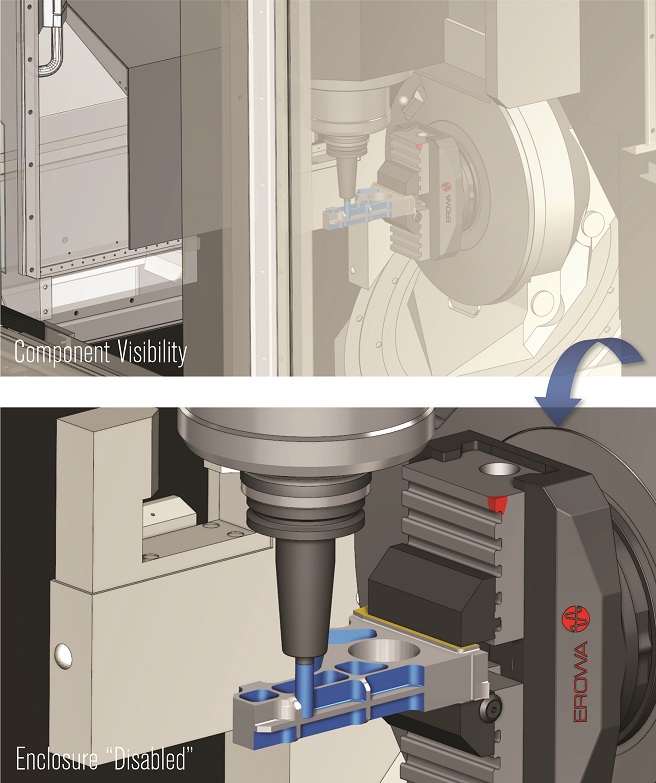

Component / Model Visibility

Quickly see unobstructed views of the cutting process and gain better access to the part by removing objects with “Invisible” and “Disable” actions. “Invisible” hides objects (components or models) from view, but they still exist in the simulation for collision detection. “Disabled” omits the object from simulation by hiding it from view and ignoring it for collision detection.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan